South Mountain Division

Mid-East Region – National Model Railroad Association

Draft Meeting Minutes – May 19, 2019

There was no SMD business meeting in April because the Division hosted its annual Mini-Con.

Division members met at Bill Wilson’s home in Mt. Airy, MD. 17 or so were present. After viewing the host’s layout and socializing, Superintendant Alex Polimeni called the business meeting to order.

19.5-1 Paymaster’s Report: Paymaster Ray Price reported that the Division has $4357.47 in its bank account including the proceeds from the 2019 Mini-Con and the white elephant sale held at that event. The Paymaster reported that expenses for the Mini-Con have been reimbursed.

19.5-2 Clerk’s Report (Meeting Minutes): Clerk Harvey Heyser summarized the draft minutes (previously distributed by e-mail). Bob Johnson made the following motion (seconded by Brian Greenawalt):

Motion: That the draft Minutes for the March 2019 meeting be approved as submitted. The motion passed unanimously.

Old Business:

18.10-4 2019 Mini-Con Recap: In the absence of Chair Pete Clarke, the Superintendant thanked all who participated and reported the following. 232 attended – the most ever. The raffle produced $220 in proceeds; the white elephant table produced $133 in proceeds. Expenses for the SMD of $28 resulted in the Division bank account balance increasing by approximately $325. Brian Wolfe and Pete Clarke have expressed their interest in doing another Mini-Con in 2020.

Reimbursing Mainline Hobbies for their expenses in renting the Fire Hall and publicizing the event: There was a discussion of what to do with the proceeds. Last year, the SMD bought a page in Mainline’s fall layout tour book. Since the white elephant table was more successful than anticipated, concern was expressed that sales at the Mini-Con might detract from Mainline’s business. It was suggested that the SMD take a table at a local train show instead of having the white elephant table at the Mini-Con. It was noted that some people who placed items on the table intended some or all of the proceeds to be donated to the Division. The discussion concluded with a consensus to get Mainline involved in the decision of what to do with the proceeds and whether to continue to have the white elephant table.

Harvey Heyser made the following motion (seconded by Tom Fedor):

Motion: That the SMD take out a page in the Mainline fall layout tour book.

Bob Johnson proposed the following amendment: That the discussion of profits be tabled until a future meeting.

As the amendment was acceptable to those proposing the motion, the following amended motion was discussed and voted on:

Amended Motion: That the SMD take out a page in the Mainline fall layout tour book and that the discussion of profits be tabled until a future meeting. The motion passed unanimously.

Before the vote, the Superintendant clarified that neither the amount nor the source of the funds (raffle or white elephant proceeds) was specified by the motion. The Superintendant will coordinate with Pete Clarke.

19.3-4 E-mails to Members: Superintendant Polimeni reported continuing difficulties reaching addresses from the Division’s G-mail accounts. People can communicate with the Division, but we cannot send out e-mails to multiple addresses. (The SMD is considered “junk mail.”) There may be a way to fix the situation. The Superintendant will continue trying.

New Business:

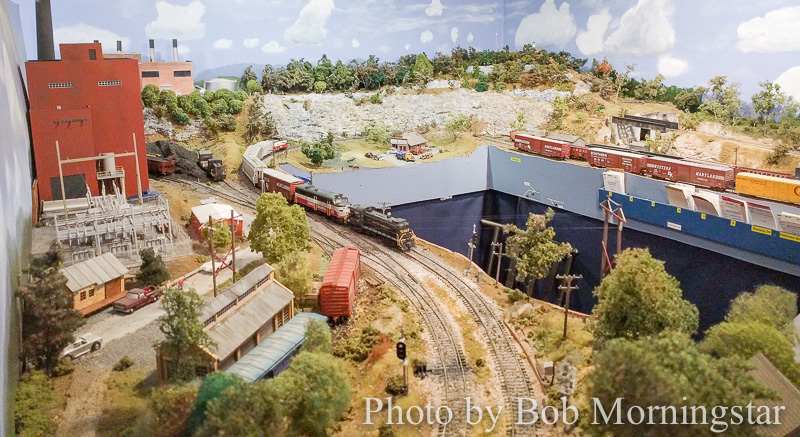

19.5-3 Host Bill Wilson welcomed everyone to his freelanced HO 1950’s B & O layout.

19.5-4 Election of Officers: The Superintendant distributed a statement regarding the election of officers (prepared with reference to the by-laws and with input from Tom Fedor). Those present reviewed and discussed the statement. It was noted that Nominations Chair Scott Schill was no longer an NMRA member, but he had indicated to the Superintendant that he had received no nominations other than for the current officers. The current officers took responsibility for not more closely following the by-law provisions. Postponing the election until a special meeting in June was discussed

Bob Johnson made the following motion (seconded by Jeff Adams):

Motion: That the SMD temporarily suspend pertinent sections of the by-laws and proceed with the election. The motion was passed unanimously with 2 abstentions (Paymaster and Clerk – conflict of interest) and with the Superintendant not voting (per Robert’s Rules of Order).

The Superintendant called for nominations from the floor. There were none. Dave Thalman made the following motion (seconded by Don Florwick):

Motion: That the nominations for election of officers for the 2019-2020 year be closed. The motion was passed unanimously with 2 abstentions (Paymaster and Clerk – conflict of interest) and with the Superintendant not voting (per Robert’s Rules of Order).

Don Florwick made the following motion (seconded by Brian Greenawalt):

Motion to cast a unanimous ballot for re-election of the current officers. The motion was passed unanimously with 2 abstentions (Paymaster and Clerk) and with the Superintendant not voting (per Robert’s Rules of Order).

There was discussion of the need for Division members to share the load and to be willing to take elected positions. It was also noted that the Superintendant relies on his (appointed) Advisory Committee – all members with experience as elected officers.

19.5-5 Reading Railroad Prototype Modelers Meet, September 13-15, 2019: Flyers provided to the Division were passed out. Information is available at www.ReadingRRMM.com.

19.5-6 SMD Yahoo group: Since current moderator Andy Dodge has left the Division, Tom Fedor will take over that position.

19.5-7 Year end review and future plans: The Superintendant reported the Division is active and the Mini-Con is very much appreciated not only by area modelers but also by the MER. He still has things he has not accomplished especially related to digital exposure for the Division and to the achievement program.

19.5-8 Recruiting new NMRA and SMD members: The need to reach out to Mini-Con attendees was brought up. Also brought up was the desire to reach out to local clubs and museums. Problems with the G-mail account (item #19.3-4 above) have hampered efforts to reach out by e-mail.

19.5-9 Frederick Model Railroad Club: Tom Fedor reported the Club may have to move their 80 ft baggage car. The land owner is contemplating sale of the property in the next couple of years. Any ideas or leads will be appreciated.

19.5-10 Future meeting site: Jeff Adams indicated the Western Maryland Ry. Historical society would be interested in hosting an SMD meeting.

Adjournment: The Chair accepted a motion to adjourn. Notice of the fall meetings will be communicated to the members.

Minutes submitted by Clerk Harvey Heyser

Following the meeting, member Bob Geldmacher, who works in association with Scenic Express, gave an extensive and detailed review and demonstration of scenery products currently available. Not only did he have numerous samples for viewing, but he also demonstrated how those samples are applied.

The SMD monthly business meeting, previously scheduled for Sunday, 13 Oct., has been moved to 20 Oct., due to a conflict with the MER’s annual convention, The Liberty Bell Special.

The SMD monthly business meeting, previously scheduled for Sunday, 13 Oct., has been moved to 20 Oct., due to a conflict with the MER’s annual convention, The Liberty Bell Special.

The Bunker Hill Model Railroad’s next show is October 5th, 2019. If you are planning on selling at this show see our new website for more information at

The Bunker Hill Model Railroad’s next show is October 5th, 2019. If you are planning on selling at this show see our new website for more information at