Draft Meeting Minutes – September 11, 2022

Division members met remotely on the internet using the Zoom platform. 14 or so were present. In Superintendent Bob Johnson’s absence, past Superintendent Alex Polimeni chaired the meeting. Heopened the Zoom session prior to the published start time for logging in and sharing.

During the lead-up to the meeting, the following was shared:

The Chair called the business meeting to order at about 2:30 pm.

22.9–1Paymaster’s Report: Paymaster Ray Price reported the SMD bank balance was $3,507.91. That balance does not reflect the $50 contribution to the Greencastle High Line Station Fundauthorized by motion at the May meeting (Item # 22.5-6). The Paymaster requested forwarding information. It was not clear whether the balance reflected payment for the 2022-23 Zoom renewal ($157.40).

22.9-2Clerk’s Report (Meeting Minutes): As mentioned above, members were not able to review the draft minutes prior to the meeting. In addition, the Chair reported the Superintendent’s plan to handle the minutes in a different manner. As a result, approval of draft minutes was deferred until the October meeting. Clerk Harvey Heyser requested member feedback on several uncertain matters related to the March and May minutes. Members shared the following:

March 2022 – During the Clerk’s Zoom disconnection, members approved the February 2022 draft minutes as submitted and focused on the Mini-Con during the following discussion.

May 2022 – The motion made to elect by acclimation was for the entire slate of officer candidates (not only for Superintendent). No one else was running.

22-9.3Future Minutes: The clerk indicated he is unlikely to be able to attend upcoming meetings in-person and requested assistance with note taking. The Chair suggested the Clerk forward a list of his requirements for the notes and for electronic document transmission. The Clerk will continue to formatthese notes into formal minutes. The Clerk will be able to attend by Zoom or by phone – neither alternative entirely reliable for hearing group discussion in a larger space. The Chair will investigate a microphone more suitable for the situation.

Old Business: There were no items of old business discussed.

New Business:

22-9.4A Planning Meeting was held prior to this regular membership meeting. The Chair reported that

the Superintendent is excited about the coming year and has plans worked out for the year’s meetings –plans he will share in person. With regard to clinics, Don Florwick suggested polling members on which subjects they are interested in learning about and which subjects they would be willing to present.

22-9-5Future Meetings: September’s meeting hopefully will be the last remote meeting. The schedule of hosts for face-to-face meetings is as follows (subject to confirmation):

October 2022 – Bob Johnson

November 2022 – Paul Mahoney

December 2022 – Jeff Grove

May 2023 – Rich Randall

Others who have indicated a willingness to host: Andy Dodge and Pete & Jane Clarke.

22-9.6Wheel Report: Editor Alex Polimeni reported his plans to publish the Fall 2022 issue soon and then to adjust the future publication schedule to better coordinate with future Mini-Cons. It was noted that any increase in the number of issues will depend on additional submitted content. A Modeler’s Corner with captioned photos was suggested.

22-9.7Mini-Cons (general): The loss of audience for formal clinics after lunch was discussed and several suggestions were made: 1) extend time for the informal clinics into the afternoon, 2) run the activities through lunch time, especially if an on-site food option is available, 3) schedule a roundtable discussion for lunch to give informal clinicians a break, 4) finish the event about 2 p.m., and 5) schedule a “heavy-weight” speaker to wrap-up things – suggestions; Bob Geldmacher talking about scenery and someone speaking about decoder installation.

Publicity: Don Florwick requested information more in advance of the event to account for magazine deadlines and to reach other NMRA Divisions (not possible in 2022 because of the late decision to hold the 2022 event). He also repeated the need to reach a wider audience (parents with kids, for instance).

Food: The 2022 vender had reasonable business. Nearby Rouzerville has numerous options.

22-9.8An NMRA Alternative for Remote Meetings/Clinics: As a way to save the SMD money, Harvey Heyser asked whether National has any plans. Bob Morningstar will look into that. Although hopefully this September meeting will be the last remote meeting, remote hobby hang-outs may happen.

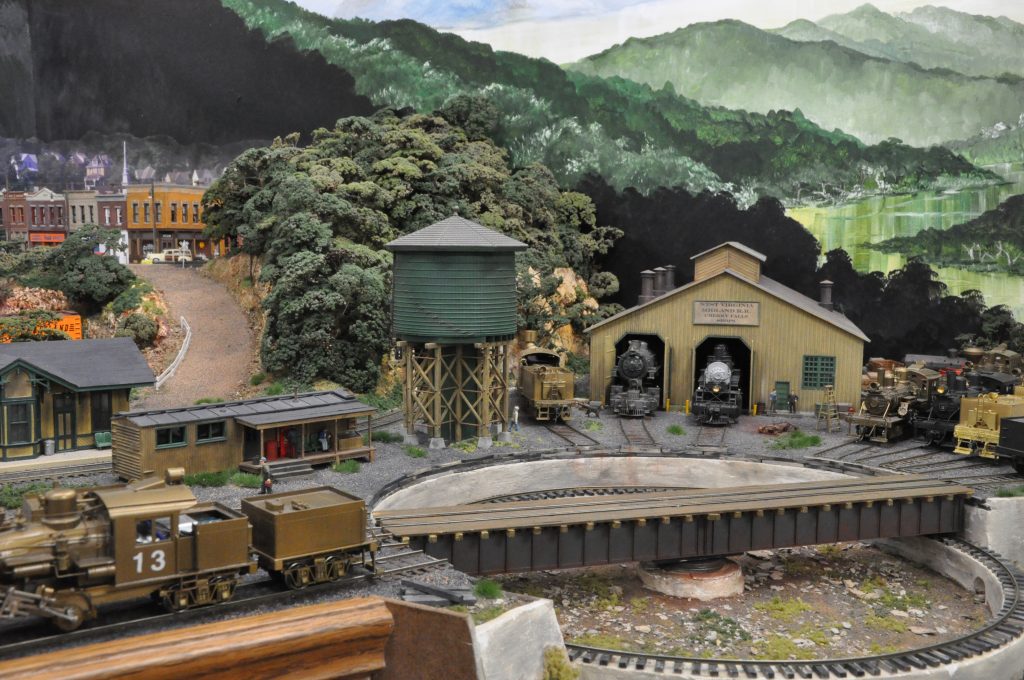

22-9.9Bob Johnson’s Layout: Harvey Heyser urged members to take a good look at Bob’s town of Diana, an excellent example of small layout design.

Adjournment: The Superintendant accepted a motion to adjourn. The next meeting on October 9, 2022 will be held at 2:00 p.m. at Bob Johnson’s home in Jefferson, MD. It will be an in-person, face-to-face meeting. Members will be reminded by e-mail.

Minutes submitted by Clerk Harvey Heyser

There was no clinic scheduled following the September business meeting. The following was shared: